Choosing the Right Access Cover for Your Next Project

Choosing the right access cover for a particular application is vital to the prevention of problems and product failures in the future. When choosing access covers for your next project, there are eight key factors to consider. They include: loadings, size, aesthetics, security, gas tightness, water tightness, cover orientation and handling. To provide a clear picture of how to choose an access cover perfect for your project, let’s examine each of these factors briefly. If you require further help choosing an access cover, ACO’s Technical Services Department can offer additional advice. At each heading, click on the link for more detail.

Loadings

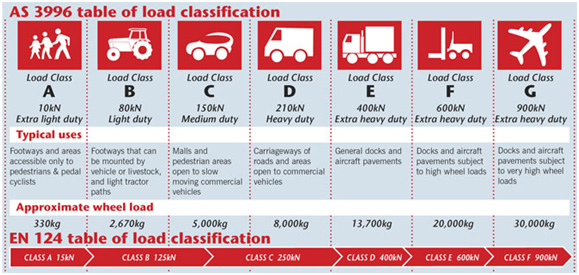

When deciding on suitable loading requirements, a load class will need to be established. In order to do this, first consider:

- Type of traffic – consider the weight of different types of traffic, particularly trucks, trolleys and forklifts which may carry larger loads

- Frequency of traffic – more frequent traffic may require a heavier load class

- Speed of traffic – fast moving traffic can intensify the load effect on the access cover

- Position of access cover – if the access cover is positioned where traffic will be turning, braking or if the cover is installed at the bottom of a ramp, it will be subjected to extreme forces and may require a higher load class

- Wheel type – a heavier duty cover may be required for areas traversed by solid tyres which exert loads through smaller contact areas than pneumatic tyres

The following table outlines appropriate load classifications for the weights of the loadings. However, keep in mind that the above factors can influence the load.

As a part of our continuous product development and commitment to quality, we use NATA certified testing equipment which is operated by fully trained and certified technicians.

Size

ACO access covers are available in various sizes and configurations. We always measure the width along the side of the cover that is parallel to the lifting edge and the length along the adjacent edge. We offer single part access covers as well as two-part, three-part and trench run access covers, systems in which multiple covers are seated lengthways on a single frame. Multi-part access cover systems consist of multiple covers seated both lengthways and widthways on a single frame. In the multi-part system, removable beams support the covers.

Aesthetics

A choice of infill materials for recessed covers offers the option of filling the cover with materials that match or complement the surrounding pavement. Also consider decorative edging, which is available in stainless steel or brass and can be fixed to the edge of the cover and frame for an attractive finish.

Security

For additional security, locking bolts can be added to the access cover. Many of our regular and recessed access covers include locks as standard.

Gas and Water Tightness

All of our standard covers are gas and water sealed as standard, to normal atmospheric pressure. The types of seal we use also prevent odours escaping or entering. For applications where back pressure is higher than normal atmospheric pressure, locking bolts are added to prevent the entry of gas or water.

Cover Orientation

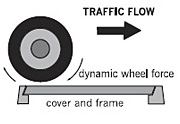

To prevent the cover from lifting, the cover needs to be positioned so that the drawcut edge faces the orientation of the traffic. Access covers should be positioned to avoid obstacles such as walls, kerbs and barriers that could obstruct removal of the cover.

Handling

For the safety of service people, we also supply assisted lift access covers for applications where frequent access to utilities or machinery beneath is required. The Servokat access cover range consists of covers which are hinged to their frames with a gas strut which allows for easy opening.

To learn more about choosing the right access cover for your next project, get in touch with ACO’s Technical Services Department.